Advantage

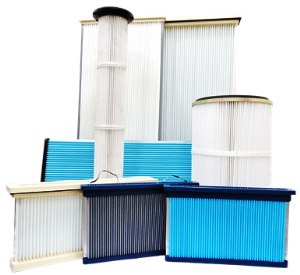

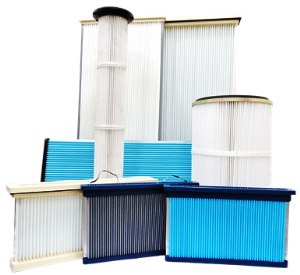

2-3 times more filtration area compared to conventional filter bags. The volume of equipment is obviously reduced.

Self-supporting, without cage, no damage caused by the friction between filter and the cage.

Surface treatment by MF(Microporous Finish). The filtering mechanism is different from that of conventional filters. Except getting high efficiency, it reduces the dust penetration into the filter media and extends the service life of filters.

The strength of unit weight is much higher than that of traditional filters. Compared with traditional filters, it is more light, stronger and durable.

Simple and quick to fit and replace. Shorten shutdown duration and less impact to production line.

Can be retrofitted into existing units.

Characteristic

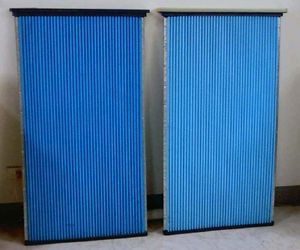

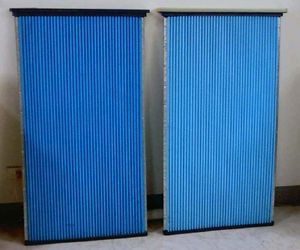

The resilient mounting flange provides excellent airtight in installation of filters. The mounting flange is an integral whole and combines with the filter compactly.

Aerodynamic shape optimizes air flow during filtering and cleaning.

Continuously bonded pleats ensure a stable but flexible form. Wide folds make dust shook off effectively by air pulse.

Rugged base supports and protects the filter element.

Special filter media suit a variety of applications.

Edge seals provide support and stability.

Difference

MF fabrics have a specially designed surface with a controlled pore size which reduces dust penetration into the fabric.

Conventional needlefelts have less well defined random sized voids between fibers, through which particle impregnation occurs more rapidly.