Characteristic

Filter solid particulates and pollutants from gas streams.

Operate at up to 900°C Are highly efficient-emissions around (< 3mg/m3)

Aluminosilicte ceramic composition

Are very resistant to acid gases.

Self supporting

Monolithic construction

High porosity-86%

Are highly efficient-emissions around (< 3mg/m3)

Aluminosilicte ceramic composition

Are very resistant to acid gases.

Self supporting

Monolithic construction

High porosity-86% Rigid

Integral flange

Low density

Rigid

Integral flange

Low density

APPLICATIONS

Waste incineration

Non-ferrous metal melting and processing

Fluidised bed metal cleaning

Chemicals manufacturing

Boilers

Glass melting furnaces

Cement clinker cooling

Minerals drying

Coal processing

CERAFIL BENEFITS TO THE END USER

Competitive capital and running costs

Low emissions

Compliance with current and future particulate emission legislation

Ability to handle over-temperature operation without damage

Potentially simple abatement scheme

Reliable, easily maintained filter plant

Cerafil TopKat benefits

Incorporates integral catalyst

–Oxidise dioxins & VOC’s

–NOx removal (with ammonia or urea)

No diffusion restrictions due to micron sized catalyst particles-gives much more efficient utilization of the catalyst material

Catalyst material can be composed with no regard to structural/mechanical strength

High efficiency & energy saving capability

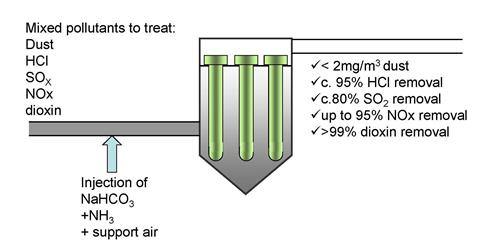

The advantages of ceramic(catalyst) filter applied in the flue gas of incineration system are as followings

It can be operated between 350 and 450℃.

It can capture 0.1 m diameter particle with efficiency 99% that equals to HEPA grade filtration. The dust collection efficiency can achieve 99.9%. The dust concentration of the exhaust is very low (<3mg/m3).

The catalyst ceramic filter can catalyze and oxidize the dioxin directly. The benzene link is destructed and transferred to gaseous H2O + CO2 + CO. It is not necessary to add fast quenching tower to avoid dioxin generation.

Ammonia can be injected into the flue gas, after the dust is captured by the ceramic filter, NOx will be oxidized by the catalyst inside the ceramic. NOx will be transferred into gaseous N2+H2O. The DeNOx efficiency can achieve 95%. The energy waste due to flue gas temperature reduction and reheating can be avoided. The capital and operation cost of the heating facility can be saved.

The dry spray injection can be directly used to remove the acid. Under high temperature operation, DeSOx efficiency can achieve 80% and HCL removal efficiency can achieve 95%. It is not necessary to add semi-dry spray tower to remove the acid.

Summarize aforesaid, The ceramic (catalyst) filter is a high efficiency and multi-pollutants simultaneous removal dust collection device.

Smaller space and area required.

Simplified system operation.

Lower capital and operation cost compared with the traditional treatment way.

The discharged ash is dry solid without pollution. No more treatment is needed. It can be piled.

Considering the heat recovery, the economizer and air preheater can be installed downstream the ceramic filter. The problem about heat recovery efficiency affected by the dust deposit will not exist.

If the flus gas contains high concentration of acid, the acid removal scrubber can be installed downstream the ceramic filter.